Table of Contents

- Introduction

- History of Aluminum

- Why Aluminum is Most Commonly Used

- Types of Aluminum and Their Uses

- Summary of Aluminum Types and Applications

- Products for Aluminum Uses in Industry

- Applications of Aluminium in Daily Life

- Most Common Grades of Aluminum

- Conclusion

Introduction

Aluminum is the third-most-abundant element in Earth’s crust and is used in modern industry and daily life. It is used in everything from the household to important components in aerospace and construction.

History of Aluminum

The history of aluminum dates back to the early 19th century. It was initially even more precious than gold since it was too hard to extract from its sources. It was only with the advent of the Hall-Héroult process in 1886 that aluminium production became cost-effective, and its use spread throughout the planet.

Why Aluminum is Most Commonly Used

The name suggests that Aluminum is a ‘Go-to’ metal for nearly about every other application due to the following properties:

- Lightweight: Reduces transportation and structure costs.

- High Strength: Makes it durable.

- Corrosion Resistance: Avoids the deterioration of products.

- Conductivity: This makes it indispensable for electrical applications.

- Recyclability: This makes it cost-effective, as it is an eco-friendly metal.

Types of Aluminum and Their Uses

Aluminum is a versatile metal that comes in various forms, each with unique properties and applications. Here are the main types of aluminum and their common uses:

Pure Aluminum

Pure aluminum doesn’t contain any alloying elements. It will contain a minimum amount of contaminants. Aluminum represents soft, ductile, easy corrosion, and electrically conductive properties. Such properties are rather often utilized in non-load-bearing elements, like wires, cables, foil, and other decorative items

Cast Aluminum

Cast aluminum products are merely aluminum alloys that are melted, conducted into molds, and finally formed into the required shapes. Casting ensures to be an economical way to produce a great volume of several parts, including engine components, prosthetic parts, and decorative items.

Anodized Aluminum

Anodized aluminum is aluminum or an aluminum alloy whose surface has been made harder and more durable through electrochemical reactions. Anodizing can also create different-colored surfaces with a matte or lustrous finish. Anodized aluminum is often used in construction, architecture, transportation, and consumer products

Wrought Aluminum

Wrought aluminum and aluminum alloys are shaped using forming processes like extrusion, rolling, or forging. These processes are used to form billets, rods, and ingots for other manufacturing processes such as machining. Wrought aluminum is used for machining and sheet metal fabrication to make parts for the automotive, aerospace, medical, and consumer product industries

Clad aluminum

Clad aluminum is that wherein core aluminum has various metals as a surface layer, which provides much-enhanced properties, for example, corrosion resistance and electrical conductivity. Select the proper solution depending on your application, with the mechanical strength, conductivity, and weight requirements. Compare various alloys—be that strength in 2024 or versatility in 6061—plus check the cladding material to ensure reliability. See the manufacturing processes and quality standards. And, of course, associate the cost with the performance benefits over the longer term.

Summary of Aluminum Types and Applications

- Pure Aluminum (1000 Series): Used in wires, cables, and foil.

- Aluminum-Copper Alloys (2000 Series): Used in aerospace and military vehicles.

- Aluminum-Manganese Alloys (3000 Series): Used in drink cans and roofing.

- Aluminum-Silicon Alloys (4000 Series): Used in car engine parts and welding wire.

- Aluminum-Magnesium Alloys (5000 Series): Used in marine applications and automotive parts.

- Aluminum-Magnesium-Silicon Alloys (6000 Series): Used in building frames and pipelines.

- Aluminum-Zinc Alloys (7000 Series): Used in aircraft parts and sports equipment.

- Aluminum-Lithium Alloys (8000 Series): Used in spacecraft and advanced sports gear.

Products for Aluminum Uses in Industry

Various products are designed to utilize the unique properties of aluminum across different industries. Here are some key products:

Aluminum Sheets

Aluminium sheets are flat, thin pieces of aluminium commonly used in various industries for their lightweight, corrosion-resistant, and formable properties. They come in various alloy compositions, tempers, and thicknesses to suit specific purposes.

Aluminium sheets are used in automotive and construction industries like car bodies, roofing, and siding, apart from other applications.

Example: On CNBC, we found an article regarding the fact that the automotive industry increasingly uses aluminium sheets to build lightweight and fuel-efficient vehicles.

Aluminum Plates

Aluminum plates are flat sheets of aluminium metal widely used in building, manufacturing, and other industrial purposes. They are lightweight yet robust, resist corrosion, conduct heat efficiently, and are simple to form and weld. These plates come in various thicknesses and widths, making them suitable for various applications due to their durability and flexibility.

Uses: Aerospace industries and for building aircraft structural body frames.

Example: Reuters indicates that the aerospace industry uses aluminium plates to maintain increased operation efficiency and safety in aeroplanes.

We offer best Aluminium Plates Prices in India

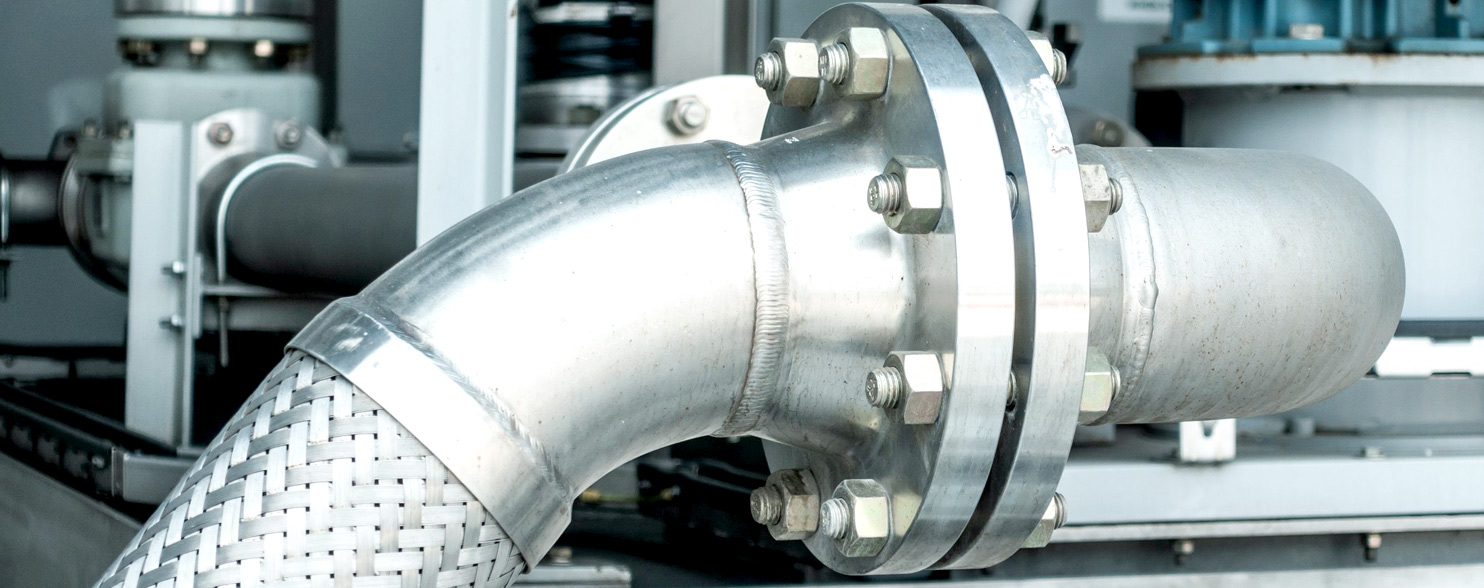

Aluminum Flanges

Aluminum flanges are flat, ring-shaped pieces with holes in the centre. They join pipes, tubes, and other components by bolting them together face to face. They are corrosion-resistant, robust but light, and simple to work with. They are widely employed in pipeline systems, hydraulic and pneumatic applications, and industrial machinery. Aluminum flanges are available in a variety of forms, diameters, and bolt patterns to meet specific connection needs.

Uses: To connect pipes securely in piping systems, especially in the oil & gas industry

Example: Aluminum flanges are used to maintain the integrity of the pipelines used in oil and gas.

Aluminum Round Bars

Aluminium round bars are cylindrical rods. They are solid, with a circular cross-section along their entire length. They offer a high strength-to-weight ratio and corrosion resistance. They are widely used in construction, machinery, and fabrication for applications like structural components, shafts, axles, and decorative trims. Available in various diameters and lengths, aluminium round bars are versatile, lightweight, and durable.

Uses: Provided in manufacturing the machinery equipment and construction for support structures. Example: Heavy machinery is being built using aluminium round bars for their tensile—described properties of strength and lightness.

Aluminum Angles & Channels

Aluminum angles and channels are structural profiles using the lightweight yet strong aluminum. Angles are L-shaped cross-sections with two perpendicular legs, used for framing, reinforcement, and support. Channels are U-shaped cross-sections, employed for framing, cable management, guiding systems, and structural reinforcement. Both profiles offer corrosion resistance, a good strength-to-weight ratio, and versatility in construction, machinery, and equipment. They come in various sizes and configurations to meet diverse needs.

Uses: Abundant in construction for framing and structural support. Example: In modern architectural design, aluminium angles and channels have been thoroughly used to create both exquisite designs and complex structures, according to The Guardian.

Applications of Aluminium in Daily Life

Extrusions

Aluminum extrusions are used in making window frames, door frames, and various structural components in buildings and vehicles.

Foil

Commonly used in packaging, insulation, and household items due to its excellent barrier properties against moisture, light, and air.

Cans and Bottles

Widely used in the beverage industry for making lightweight, corrosion-resistant containers.

Wires and Cables

Used in electrical transmission lines due to aluminum’s excellent conductivity and lightweight nature.

Castings

Engine blocks, automotive parts, and machinery components are often made from aluminum castings for their strength and durability.

Powder

Aluminum powder is used in pyrotechnics, paints, and as a reducing agent in chemical reactions.

Forgings

Strong, durable components such as aircraft parts, automotive gears, and military equipment are made from aluminum forgings.

Transportation

Aluminum is utilized extensively in the automotive and aerospace industry because of its lightness, which enhances fuel efficiency. It is used in the manufacture of various equipment used in transportation, which includes aircraft parts, automobile bodies, engine parts, among others.

Building and Construction

Aluminum is utilized in building and construction sites for window and door frames, aluminum siding, roofing and curtain walling because aluminum is strong, light and resistant to corrosion.

Conductors

Aluminum is a good conductor of electricity, and thus it is required extensively in the transmission of electricity lines such as power lines and service cables.

Durable Goods for Consumers

Its features make it the best material used in manufacturing consumer durables like cooking utensils, furniture, and tools. It is light in weight and resistant to corrosion.

Machinery and Equipment

It is used in the making of machinery and equipment parts such pumps, compressors, machinery components, and others because of its strength and corrosion resistance.

Most Common Grades of Aluminum

- 1050: It is known for having excellent corrosion resistance and high elasticity.

- 2024: High-strength and used in aerospace.

- 6061: It has a versatile form and is commonly and prevalently used in construction and automotive parts.

- 7075: This is highly strong and used in aerospace and military applications.

Conclusion

Aluminum’s special structure makes it present in every branch of industry, making it irreplaceable in the production of not only common household goods but even very complex aerospace ingredients. Thus, adaptability, together with strength and recycling possibilities, is likely to be an important material in the future of innovations.