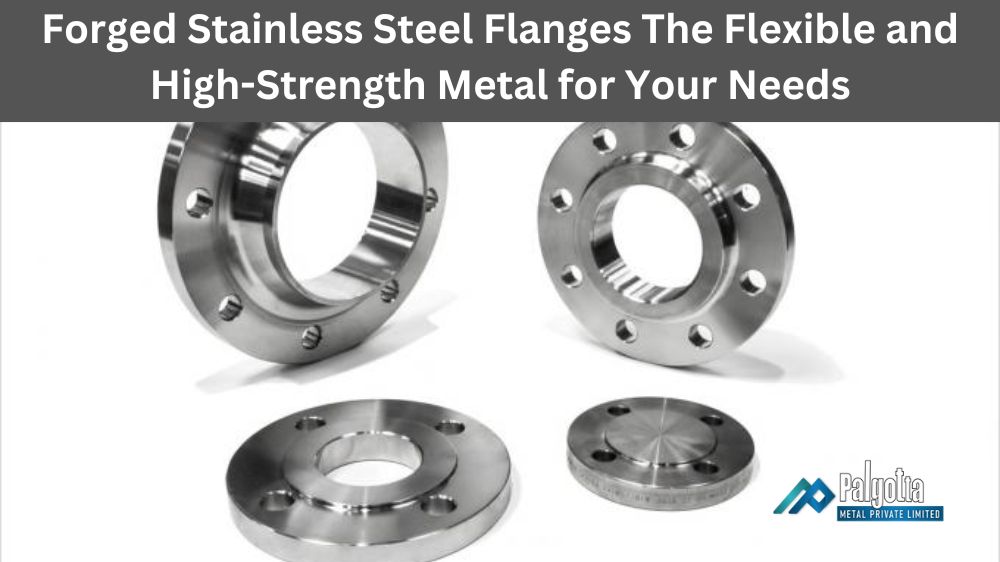

Are you looking for a flexible metal that is highly resistant to corrosion? Then look no further than forged stainless steel flanges! This component type is widely used in many industries, including construction, engineering, and manufacturing. These components are strong and long-lasting and can also be tailored to your unique needs with different sizes and designs available. In this article, we will be exploring the advantages of using stainless steel flanges so that you can determine whether or not it’s the right choice for your application. Read on to learn more about how forging stainless steel offers resilience against wear potential and an impressive strength-to-weight ratio allowing for increased flexibility compared to other metals!

One of the most common uses of stainless steel is manufacturing flanges. Flanges are connectors used to connect two pipes or other fittings. Stainless steel flanges are used extensively in the industry because of their high strength, corrosion resistance, and ability to withstand high temperatures.

In this post, we will discuss the advantages of using forged stainless steel flanges in-depth.

High Strength and Durability

Forged stainless steel flanges are renowned for their incredible strength and durability. These components are created by forming a hot piece of stainless steel (typically an alloy or cast) under pressure into the desired shape. This forging process creates flanges with superior mechanical properties compared to those produced using other manufacturing methods, such as casting or machining—they offer higher tensile strength, yield strength, flexibility, and fatigue resistance. In addition, forged flanges cost less to produce than those made through traditional manufacturing processes due to their improved material utilization and efficiency in production time. As such, they can be considered the ideal choice for many applications requiring high strength and durability.

Corrosion Resistance

Forged stainless steel flanges are highly resistant to corrosion due to their high chromium content, which makes them extremely durable and able to withstand exposure to harsh elements such as saltwater and other corrosive agents. The nickel content in the alloy also helps provide extra strength against rusting and pitting. The material is further strengthened by anodizing or electroplating, making it particularly suitable for long-term applications where frequent contact with water may occur. Furthermore, because of their strength and durability, forged stainless steel flanges are often used in high-pressure and temperature applications that require higher levels of corrosion protection than traditional pipe materials.

Versatility

Stainless steel flanges are among the most versatile equipment in pipe engineering. With its ability to be resistant to corrosion and have a wide range of temperatures that it can tolerate without being damaged, stainless steel flanges are used in various situations where durability is needed. They offer chemical and heat resistance; they don’t rust easily or break down due to mechanical impacts from high-pressure systems, and they also retain their strength with repeated use over time. In addition, stainless steel flanges come in various shapes, sizes and material grades, making them ideal for customized applications based on specific needs. This versatility makes stainless steel flanges incredibly useful and popular across industries due to their dependability when faced with harsh environments or unique application needs.

Low Maintenance

Stainless steel flanges require little or no maintenance, which makes them highly cost-effective in the long run. Their corrosion-resistant properties mean they can remain in their original condition even after years of exposure to harsh conditions. This makes them ideal for use in applications that require minimal maintenance.

Cost-Effective

While stainless steel flanges may have a higher initial cost, they are cost-effective over the long term. They require little or no maintenance and have a long working life. Furthermore, they resist corrosion, eliminating the need for frequent replacement.

Conclusion:

Forged stainless steel flanges are ideal for the industry because of their high strength, versatility, and durability. Their corrosion-resistant properties make them ideal for harsh environments, while their low maintenance requirements make them highly cost-effective over the long term. If you are looking for a reliable and versatile material for critical applications, forged stainless steel flanges are the way to go.