Do you need a reliable and sturdy flange for your industrial projects? A weld neck flange made from stainless steel is an excellent choice. With its impressive strength, corrosion-resistant properties, and vast compatibility with other materials, this versatile component adds value to applications in many industries. In this blog post, we’ll explore the characteristics of weld neck flanges made from stainless steel, including their chemical composition, various grades, pressure ratings and sizes, and some common uses where they are applied. Read on to learn more about how these remarkable components can add considerable value to your next project!

Properties

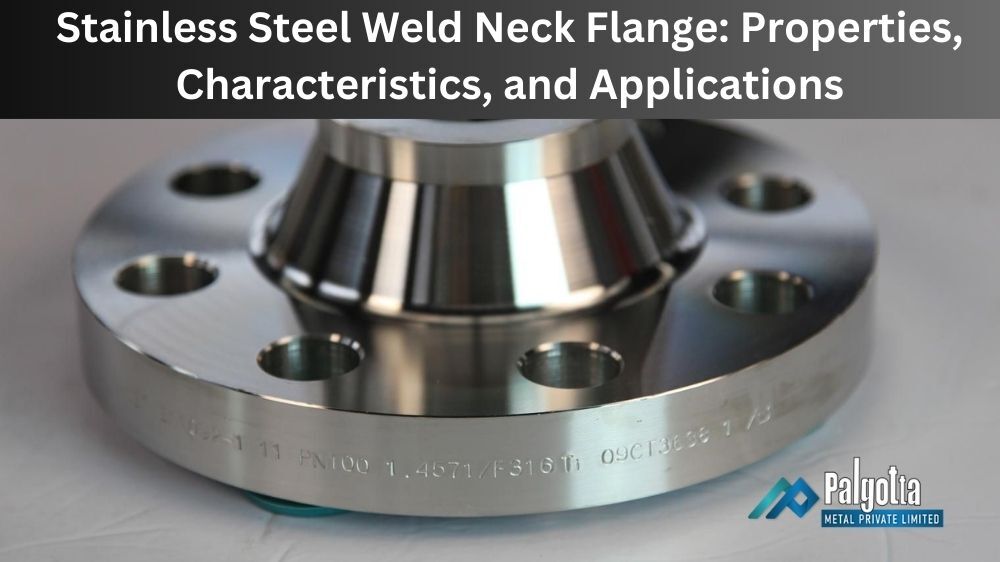

A stainless steel weld neck flange is one type of flange used in pipe fittings. Its main feature is its long tapered hub that allows the pipe’s end to be inserted and welded around the circumference. This ensures a strong, leak-free connection with good pressure tolerance. The welding also dissipates internal stresses in the flange and pipe body, increasing their strength and fatigue life. Other properties include higher temperature resistance than other standard grades, excellent corrosion resistance due to its surface finish, low maintenance cost as it does not require painting/rust prevention coating or any other kind of protective coating, and good dimensional accuracy for ease of installation.

Characteristics

Stainless steel weld neck flanges are useful in various high-pressure and industrial applications. These flanges offer exceptional durability due to their inherent corrosion resistance. They are designed to withstand temperatures above 1000°F, making them suitable for many challenging environments. Weld neck flanges have a tapered hub that allows for the efficient welding of pipes together, ensuring leak-free performance at higher pressures or temperatures. The long tapered hub also increases stability by reducing stress concentrations during welding and operation. Additionally, they come in various sizes and can be customized based on the specific application needs, such as different angles of tapers depending on the wall thicknesses. Overall, stainless steel weld neck flange is an excellent choice for any environment where strength, heat tolerance and corrosion resistance are needed.

Applications

Stainless Steel Weld Neck Flanges are a flange used for connecting pipes or other pressure-containing components. Typically, weld neck flanges are designed with heavy-duty applications in mind and made entirely of stainless steel for superior strength and corrosion resistance. These flanges have a tapered hub that protrudes from the base to ensure a secure connection to the pipe, allowing it to bear higher pressures without leaking. The weld neck also allows flexibility when creating complex piping systems, as it can be used at different angles and positions about the pipe body. They can be found in highly corrosive environments such as chemical processing plants, water treatment facilities, oil refineries, and many more industries where reliability is a top priority.

Advantages Over Other Flange Types

Stainless Steel Weld Neck Flange is advantageous to other flange types due to its strength and durability. The weld neck of the flange acts as a reinforcing rib, providing higher service pressure ratings and improved fatigue performance. Additionally, weld neck flanges are designed for frequent disassembly because of their consistent accuracy of fit, making them ideal for applications where maintenance or frequent repairs are necessary. They also offer excellent corrosion resistance in steam, air, water and chemical media, making them suitable for even the most extreme environments.

Conclusion

Stainless steel weld neck flanges are an excellent choice for pipelines requiring high-pressure and high-temperature capabilities. They offer many benefits over other flange types, including efficient flow direction and easy pipeline alignment. The flanges’ mechanical properties make them tough, strong, and corrosion-resistant. Their applications include petrochemical, chemical processing, and oil and gas industries. When choosing a flange for your pipeline system, consider the properties, characteristics, and applications of the stainless steel weld neck flange.